There was also the possibility that more than one mistake could have been made on a single patient. Will reviewed the medical records for 1,000 patients and counted the number of times an error occurred. While there were a number of other possibilities, they were excluded as being highly unlikely or realistic. Wrong route of entry (suppository not oral).The first thing Will did was to ask Nancy to list the different types of mistakes that could happen when administering meds to the patient. Will, a certified Black Belt, was assigned to help her. She requested that the hospital Process Improvement Office help her carry out her project.

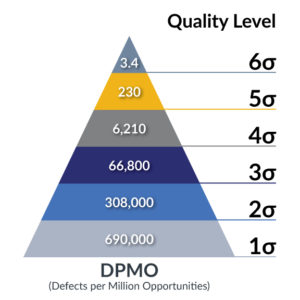

The chief nursing officer, Nancy, wanted to get a handle on how bad the problem was. An industry example of DPMOĪ large midwest hospital was concerned about an increase in errors while administering drugs to their patients. Holistic viewĭPMO forces you to identify the potential fail points in your process that could result in the creation of an unsatisfactory product or service for your customer. DPMO can be converted to the appropriate sigma level.

Many organizations refer to their quality in terms of their sigma level, with the goal being a minimum of a 6 sigma process. All can be used to compare different processes. PPM is generally used in the context of defectives, not defects. You can also use rolled throughput yield (RTY), Cpk, or parts per million (PPM). There are a number of different calculations you can use to evaluate the quality of your process. While simple in calculation, there are a number of things to understand that will make DPMO helpful in your decision-making. Flexibilityĭepending on the volume that your process produces, you can also talk in terms of defects per thousand, or hundred - or any quantity of opportunities. Much like Cpk is a generic measure of process capability that allows you to compare processes across a range of functions, DPMO allows you to compare quality and performance across a variety of different processes. Third is the total number of detected defects in your sample. Second is the number of opportunities or ways you can create a defect. To calculate your DPMO, you only need three values. It is descriptive rather than prescriptive. 3 benefits of DPMOĭPMO is a calculation of the performance of your process. Using your eyeball, you might extrapolate between those values and get 0.83 which is what the calculator above gave you. Note in the sigma table below that if you look for your DPMO of 750,000, it will fall between a Sigma level of 0.80 and 0.85. If you’re striving for a 6 sigma process, you can see that this process, which is at a 0.83 process sigma, is far from achieving that goal. Defects are the total number of defects you counted in the 50 sample invoices. Opportunities are found by multiplying your sample of 50 times your 4 possible defects. While there are a number of tables available on the internet, here’s a simple calculator that will do it for you. Your DPMO value can also be converted to a sigma level value. If your organization does not produce a large volume of output, you can also calculate defects per thousand opportunities, or defects per hundred opportunities by multiplying by the appropriate number. To calculate DPMO, you would use this formula: The formula for that is:Īs an example, you could take a sample of 50 invoices, total the count of all defects found in those 50 invoices (assume a total of 150 defects), and then divide that number by your sample size of 50 to get an average estimate of 3 defects per unit or invoice. You can use the defect frequency to calculate something we call DPU, or defects per unit. Both are defective, but certainly they are not wrong to the same degree. In our example, your invoice can have up to four different types of opportunities (for defects), which could then define your invoice as a defective invoice.Ī downside of using defectives as a measure, is that you can have an invoice with just a small spelling error in the address line, while another invoice might have an incorrect calculation, wrong address, and wrong customer name. We can then define a defective as an object that has one or more defects that may make the object unacceptable. Each defect can cause a disruption and upset your customer. Each one is an opportunity to make a mistake on the invoice that you send to your customer. For example, an invoice may have a defect or error in the address line, invoiced amount, discount, or delivery date. There can be multiple flaws or defects in an object. A defect is a flaw or discrepancy in a process or object.

Six sigma means how to#

If you’re curious as to what DPMO means, how to calculate it, what its benefits are, and how best to use it for understanding the performance of your process, read on.

0 kommentar(er)

0 kommentar(er)